Slotting is the process of

assigning items to specific pick face locations in order to gain productivity,

efficiency and accuracy. Slotting systems are meant to monitor the activity in

the pick-zone and make recommendation on when to replenish, what to replenish

and where to replenish.

In conventional slotting several attributes like the velocity of the product, order affinity with other

products in the warehouse, nature and weight of the products, location

dimensions and capacity, distance from the shipping dock, accessibility of the

locations are taken into consideration.

Now let us see some of these

attributes in detail in order to understand the science behind the slotting

process.

Velocity of the product: The more the velocity it is better to

place them close to the shipping docks as the pick volume for the product is

more

Order Affinity: For example if baseball and bat are ordered

simultaneously and hence keeping them side by side reduces the travel time and

increases efficiency and productivity. On the other hand, if the products are

very similar keeping them separate

from each other increases the picking accuracy.

Nature and weight of the products: Heavier items are placed in the

beginning of the pick route rather than fragile items in order to avoid damages

to the products.

Accessibility of the location: Bulkier items need to be placed in

the lower level in order to reduce strains to the arms and the spine.

In conventional slotting the time

horizon is fairly long between each slotting cycle say every year the company

might want to re-slot its locations. Most of the times operations are stopped

and re-slotting plan gets executed independently of the orders in the system.

In dynamic slotting, the time horizons

are very short and the pick face realignments are dynamic in nature. It runs

with the assumption of the levels of inventory in each of the existing slots is

known and when they will be picked to zero is also known. That means the demand

is known well in advance and the order or wave planning happens much ahead of

actual picking time. In dynamic slotting the number of pick-faces per item is

also dynamic in nature depending on the demand and hence more efficiency is

gained compared to conventional static slotting.

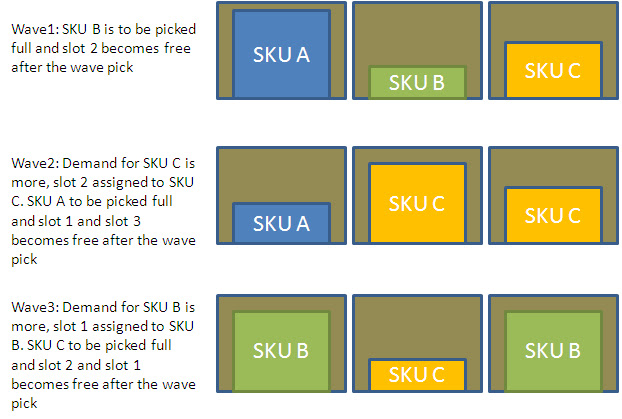

An illustration with simple order

demand attribute is given below

While the above factors

contribute to the science of slotting, deciding on what are the factors that

needs to be considered is an art. Certain factors have more weightage over

others in a specific warehouse scenario. Sometimes it is simply may not be

possible to incorporate a parameter at the product level as it tend to become

too complex and fussy. In such cases factors can be considered at part family

levels. Many times practice makes perfection. The best way is to start

implementing the factors' contributions incrementally in the slotting plan. Thus

having a successful dynamic slotting plan is an art as well as a science.

No comments:

Post a Comment